Vegetable and fruit weighing and packing machines

Very high capacity, innovative design and solutions, masterful precision, durability allowing many years of use and a lot of additional improvements making the operation more intuitive – these are only a few reasons to invest in Sorpac machines and equipment!

Our range includes professional machines for vegetable and fruit weighing, portioning and packing in a huge number of variants, so that our clients can easily find solutions to their individual needs. The automation of processes using products developed by us is essential for cost optimisation – one device is able to replace many manual workers – so they can be reassigned to more demanding work. Our machines can be used to weigh, pack or clean many types of vegetables, in particular potatoes, onions, carrots, parsley, beetroot, celery, cucumbers and others.

Automatic portioning, weighing and packing of fruit and vegetables – a guarantee for increased production capacity on your farm or enterprise.

We offer top quality machinery for production:

-

automatic scales (weighing machines, weighing hoppers – AW models) with a capacity of up to 6 tonnes per hour

-

combination / drawer scales (MW models, so-called channel scales) with capacities up to 15 tonnes per hour

-

Mesh bag packing machines with single and double thread seaming heads (mesh bag packing machines – RF models – with NewLong, Fischbein and YaoHan heads)

-

film bag packing machines (film machines – FW models)

-

brushers (B models with 10, 12 or 14 brushes) for dry cleaning of potatoes and onions, among others, in many variants

-

selection tables (ST models) up to 300 cm long for both sitting and standing work

-

weighing and packing machines (AWRM models) i.e. weighing hopper with the function of weighing vegetables up to 6 tonnes per hour and packing them in mesh bags.

-

bunkers (ZB22 models) – hopper tanks with a capacity of up to 2 tonnes, 4 tonnes or 8 tonnes

In addition, our combination scales, automatic scales, weighing and bagging machines, packing machines, mesh bag packing machines, brushing machines or inspection tables can be integrated and combined into entire vegetable or fruit weighing and packing lines.

On special request, we can also develop other production machines for you to increase the efficiency of your portioning, weighing and packing processes.

All our vegetable and fruit weighing, portioning and packing machines can be adapted to even specific applications if required – and our experienced Sorpac specialists will help you!

Efficient production equipment directly from the manufacturer

Regardless of whether you buy a selection table, brush cutter, brushing machine, channel scales, a complete line or other machines for portioning, packing or weighing your vegetables, we always offer expert warranty and after-sales service. At start-up, we will give you free instruction to familiarise you with all the functions of the equipment supplied, to increase the efficiency of the machines, to take full advantage of their capabilities and to avoid possible damage during operation.

Please check our full range of production machinery. Should you have any further questions concerning our solutions for the machine weighing, packing and wrapping of fruit and vegetables, we are here for you.

•

Multi-head weighing machines (MW models) with 4, 8, 9, 10, 11 and 12 channels are a combination scales. Weighers are used for weighing and portioning vegetables. They function is based on assembling a given portion of a product from several smaller portions.This method is very precise, which is crucial for weighing small portions. SOPRAC is offering multichannel machines on belts or on vibration feeders, which gives flexibility and high efficiency. The use of the machine is very easy thanks to the touchpad and the intuitive software.

Specification:

Use: potatoe, onion, beetroot, carrot, cucumber, etc.

Number of channels: 4, 8, 9, 10, 11, 12

Weighing range: from 0,5 up to 25 kilos

Capacity: from 20 to 30 portions per one minute, and up to 15 tons/h (depend on model, number of channels, weighing portion and type of product)

Stearing: touchpad

Power: 400V 50Hz

Air demand: 900l/h

Additional options:

– collaboration with 3 receivers

– mobile partitions (carrots or parsley weighing)

– buffer tank

•

Automatic scales AW115, AW116, AW312, AW412, AW120, AW550

Automatic weighing machines are used for portioning and bagging vegetables. They weighs a given quantity of a product and puts into a bag. It is possible to combine the scales with other automatic packaging machines. The belts have been officially approved for food production purposes. The application of steering touchpad is a novelty. The machines are highly efficient and precise during weighing process.

Specifications:

– Use: potatoe, onion, cucumber, beetroot, etc.

– Capacity: up to 6000kg per hour (depend on model, weighing portion and type of product)

– Weighing range: from 1 up to 30kg (depend on model)

– One or two belts

– Pneumatic tank closing

– Control: touchpad

– Power supply: 230V , 50Hz

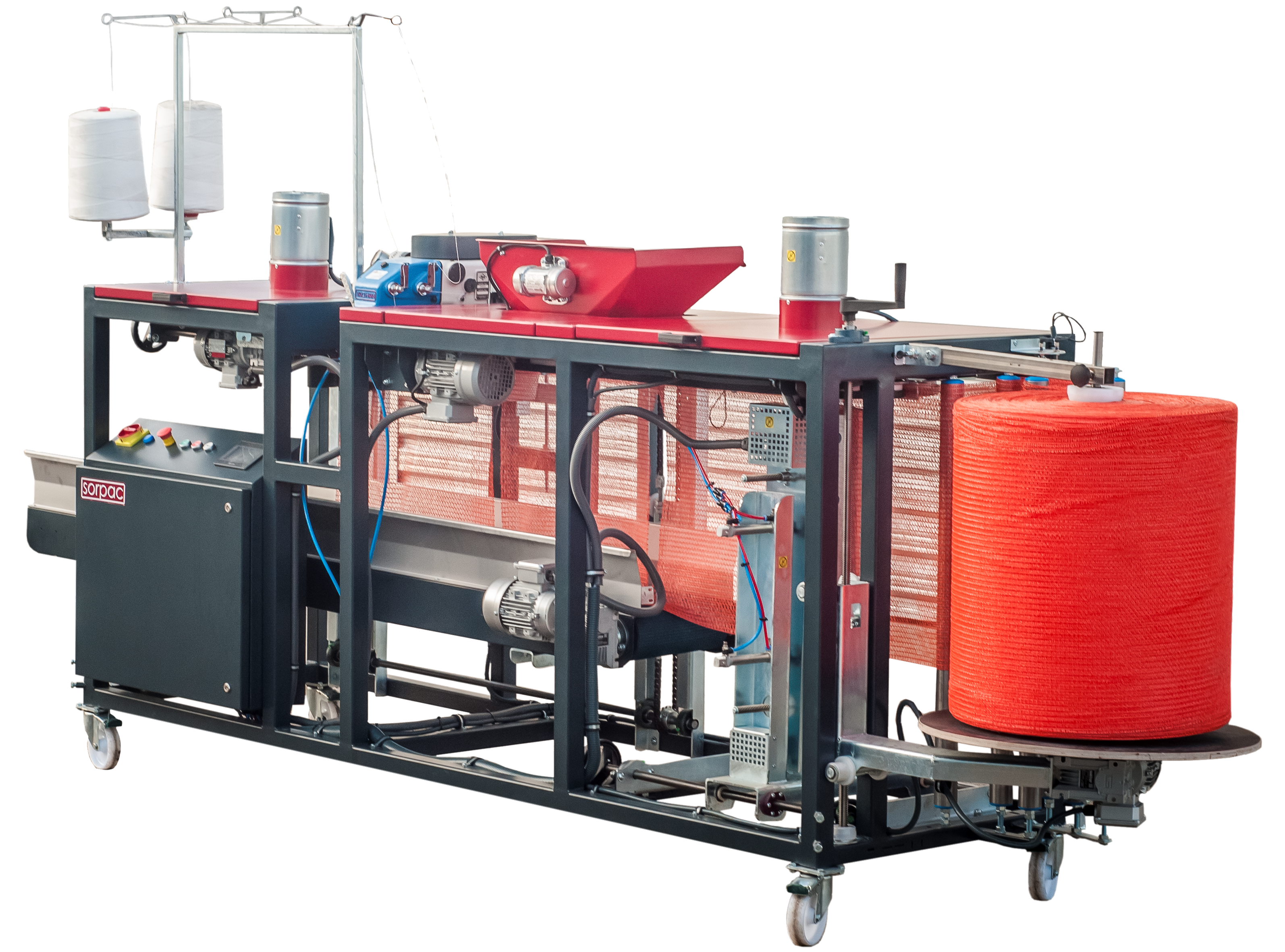

Rashel Bagging Machineare used to pack vegetables into rashel bags. A single packaging is made of a single roll of pre-sealed bags. The machines divides them and then sews the fully packed bags. It is possible to apply typical packaging sizes from 2.5 to 25 kg.

Rashel Bagging Machine can be equipped wih single or double- threads sewing head (Fischbein, Newlong, Union Special, YaoHan and other), which sews according to the desired capacity.

Technical details:

– Use: potatoe, onion, carrot, beetroot

– Capacity: Single-thread sewing head: 6t/h

– Capacity: Double-thread sewing head: 15t/h

– Size of packaging: 2.5kg – 25 kg

– Power supply: 400V/2kW

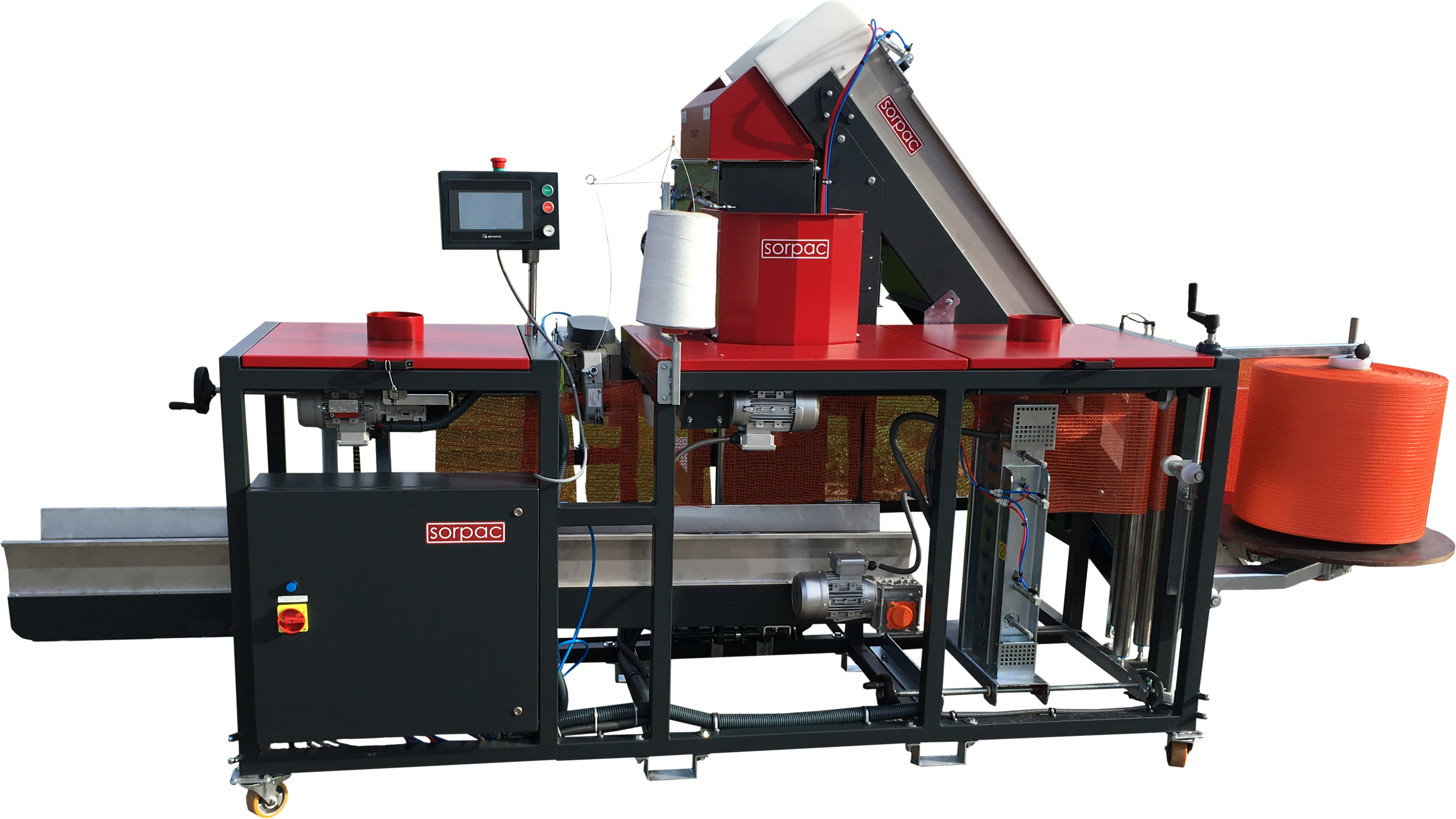

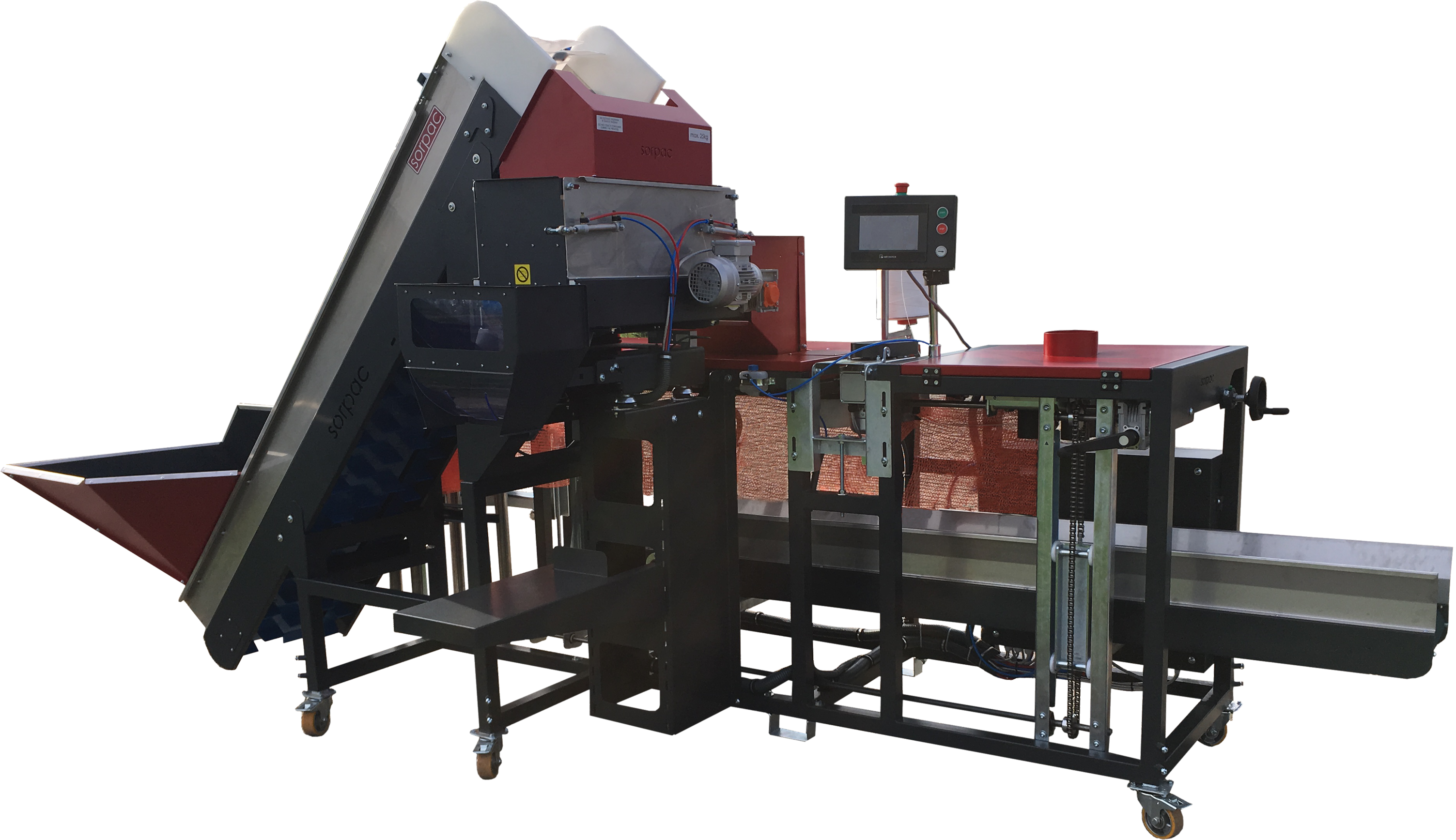

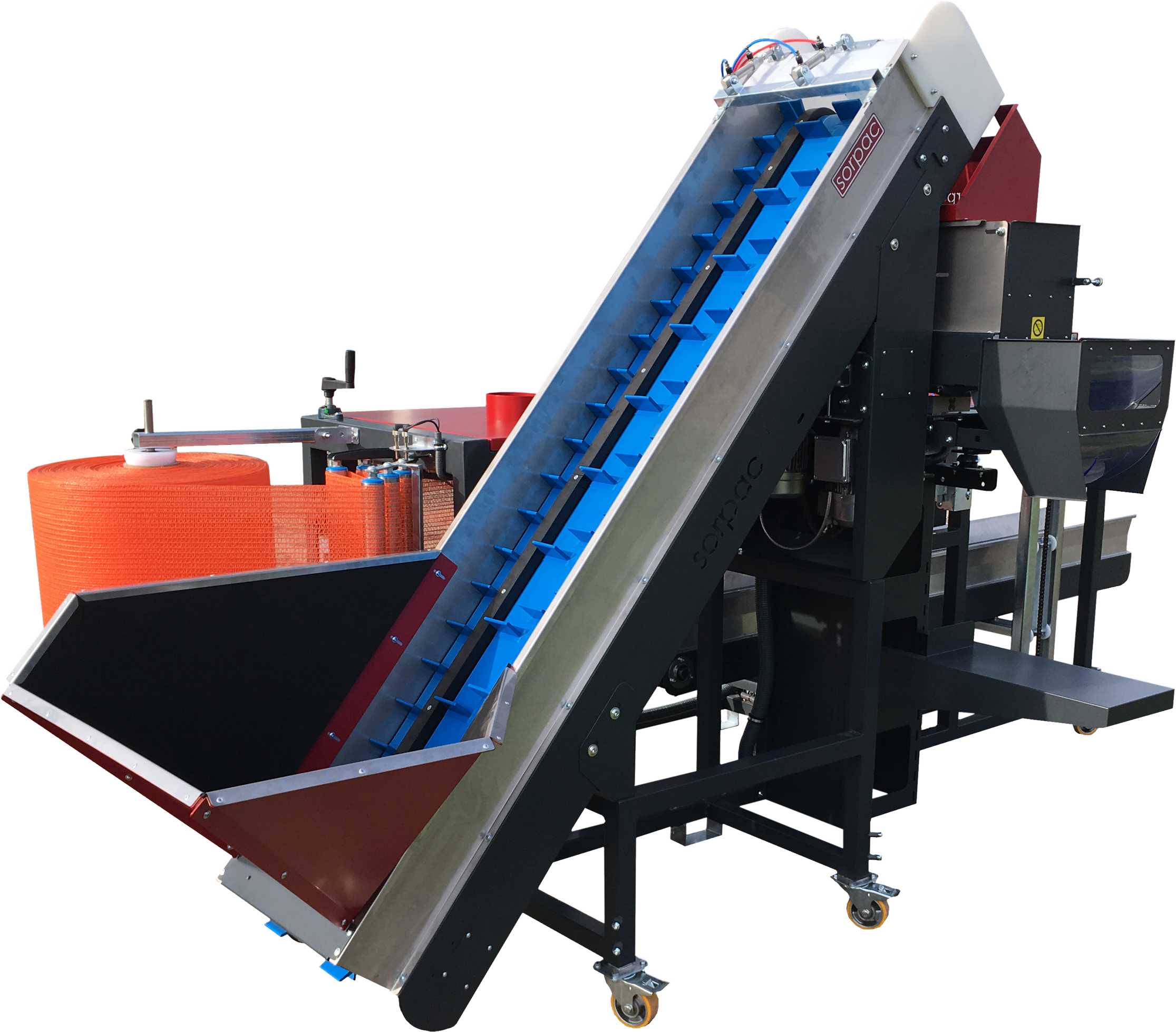

Multi-machine AWRM02 is a combination of two

machines – automatic wieighing machine and

packaging machine.

Used to pack vegetables in raschel bags.

Single pack is made from a roll pre-welded bags.

The machine portioned the goods and the weighed

portion is packed intothe bag. Then sacks sews filled

the product.

It is possible to use standard available sizes

bags for the balance 2.5 to 25kg

The machine can be equipped with a single or

two thread sewing head.

It is possible to work in manual mode and pack

bags bound.

Technical data:

Use: potatoes, onions, carrots, beets

Capacity: 6t / h

Package raschel size: 2.5 kg to 25kg

Weighing range: 1-50kg

Power supply: 400V / 3kW

Vegetable brushing machine

Use: Dry cleaning vegetables, potatoes, onions, root vegetables

Equipped with corrugated nylon brushes which do not cause any damage.

Produced in differerent versions:

width 55 cm

– B1055 – 10 brushes

– B1255 – 12 brushes

– B1455 – 14 brushes

width 80 cm

– B1080 – 10 brushes

– B1280 – 12 brushes

– B1480 – 14 brushes

width 110cm

– B1010 – 10 brushes

– B1012 – 12brushes

Optional equipment:

– Inverter for speed control

– Brush pressure parts or rubber

wash

Power supply: 400V 50Hz

Rotational speed: 180 rpm

•

Selection tables for manual selection of potatoes and onions. Produced in several sizes. Equipped with PVC pipe, aluminum or stainless steel. Equipped with inverter to control speed.

Available sizes:

ST2008 – L200cm x W80cm

ST2508 – L250cm x W80cm

ST2010 – L200cm x W100cm

ST2510 – L250cm x W100cm

ST3010 – L300cm x W100cm

ST2012 – L200cm x W120cm

ST2512 – L250cm x W120cm

ST3012 – L300cm x W120cm

Power supply: 400V 50Hz

Linear velocity: 0-0,3 m/s

•

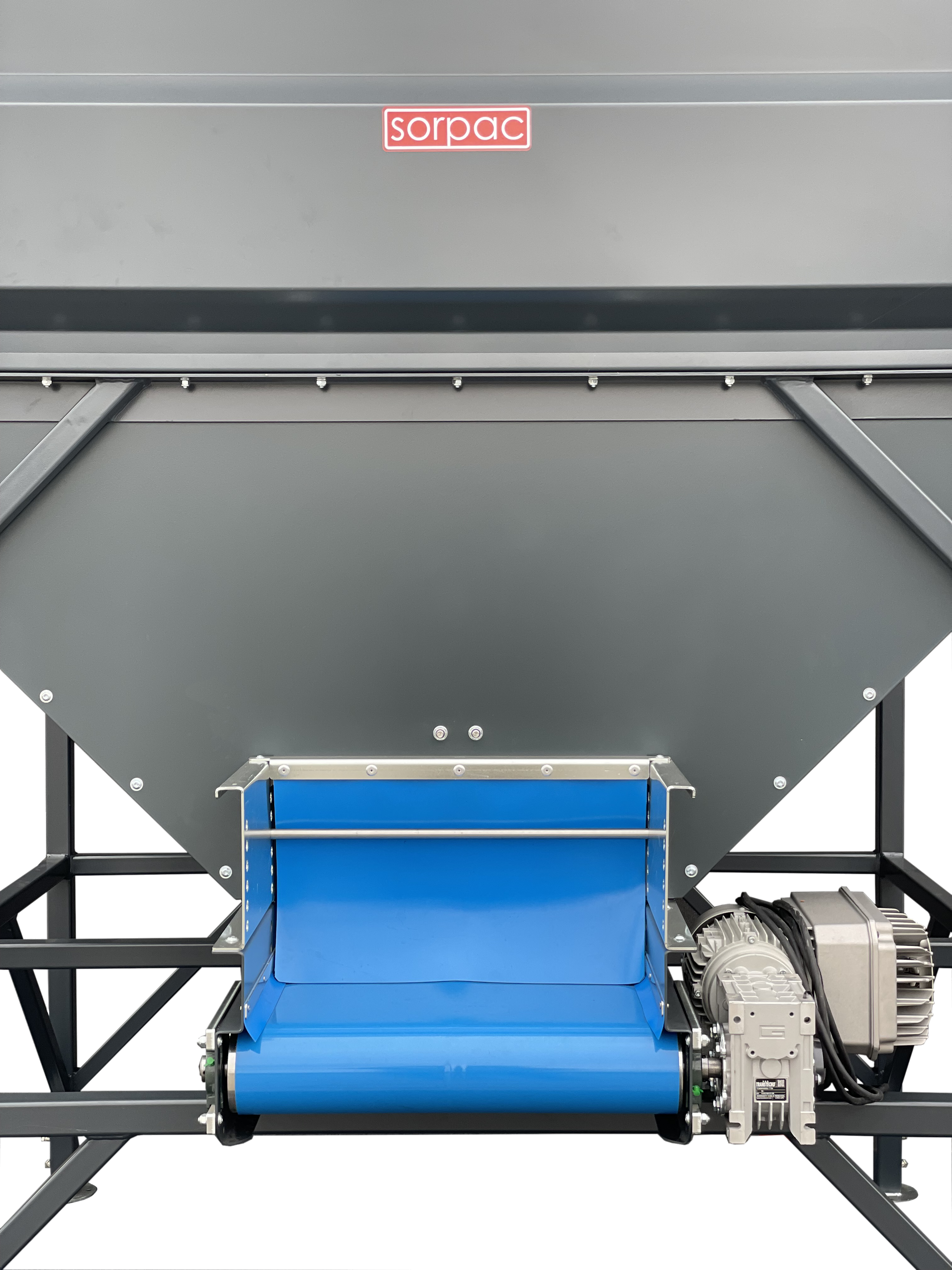

Buffer hoppers (bunkers)

ZB buffer hopper is used for collection product before packing. Provides a constant supply vegetables to a portioning, weighing and packing machine. The reservoir is made up of walls built over the dosing conveyor.

The belt is protected against the high pressure of the product. Built-in the cascade protects the product against damage. The outlet is equipped with an adjustable screen. The speed of the dosing belt is adjustable and unloading is controlled by an optical sensor.

Specification:

use: potatoes, onions, other vegetables

– speed regulation of the belt conveyor

– outlet width adjustable screen

– cascade

– possibility of unloading from two sides

– capacity: 2,5t, 3t, 4t, 5t, 5,5t

HEADQUARTERS:

SORPAC Sp.j.

ul. Golska 56,

63-233 Jaraczewo

SALES:

T: +48

792

500

330

E-MAIL: sales@sorpac.com

OPENING HOURS:

MONDAY – FRIDAY: 8.00 – 18.00

SATURDAY: 9.00 – 14.00

Wszelkie prawa do zawartości strony internetowej zastrzeźone dla SORPAC Oblizajek, Pawlak, Steinke, Sp.j. z siedzibą przy ul. Golska 56, 63-233 Jaraczewo, wpisaną przez Sąd Rejonowy dla miasta Poznań, IX Wydział‚ Gospodarczy Krajowego Rejestru Sądowego do rejestru przedsiębiorców Krajowego Rejestru Sądowego pod numerem KRS 000054

21

39, zarejestrowana jako podatnik pod numerem NIP 617

-220

-57

-83